Western Precicast Pvt. Ltd. is a distinguished leader in Medium-sized Steel casting and precision machining, recognized for its advanced infrastructure and commitment to quality excellence.

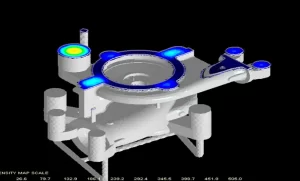

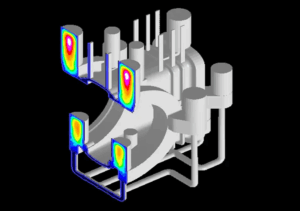

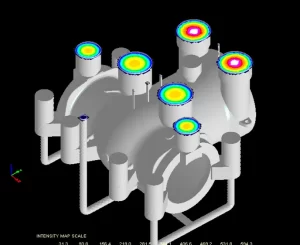

Our manufacturing capabilities include an AOD Furnace with a 12 MT capacity – Induction Furnaces ranging from 6.0 MT to 7.5 MT, and Heat Treatment Furnaces with capacities of 8 MT and 14 MT. Utilizing advanced casting simulation software, we ensure precision, consistency, and efficiency across all production processes.

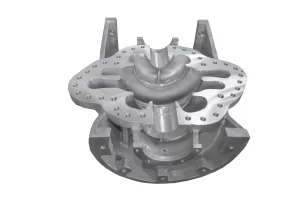

Our fully equipped machine shop houses a comprehensive range of modern machinery, including Travisan, VMC, HBM, and other high-performance equipment, enabling us to deliver diverse machining solutions with accuracy and reliability.

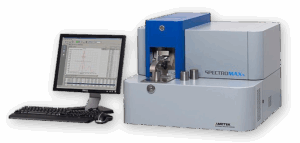

At Western Precicast, quality is our core value. Our NDE/NDT facilities are equipped for Magnetic Particle (MP), Dye Penetrant (DP), and Ultrasonic (UT) testing, along with Radiography capabilities using Linac (6 MeV), Iridium (1 enclosure), and Cobalt (3 enclosures) sources. A Spectrometer with 32 channels ensures precise chemical composition analysis.

For dimensional accuracy and inspection of machined castings, we employ a Faro Arm 3D scanner with Dia 2.7 m. Our mechanical testing facilities include UTM, Impact Testing Machines, and a range of hardness testing equipment.

Additional specialized equipment includes a Ferritoscope, Positive Material Identification (PMI) system, and In-Situ Metallographic instruments for on-site microstructure evaluation.

At Western Precicast, we take pride in our cutting-edge facilities, skilled workforce, and unwavering dedication to delivering high-quality, precision-engineered castings that not only meet but consistently exceed industry standards and customer expectations.