About Jsons foundry Pvt. Ltd.

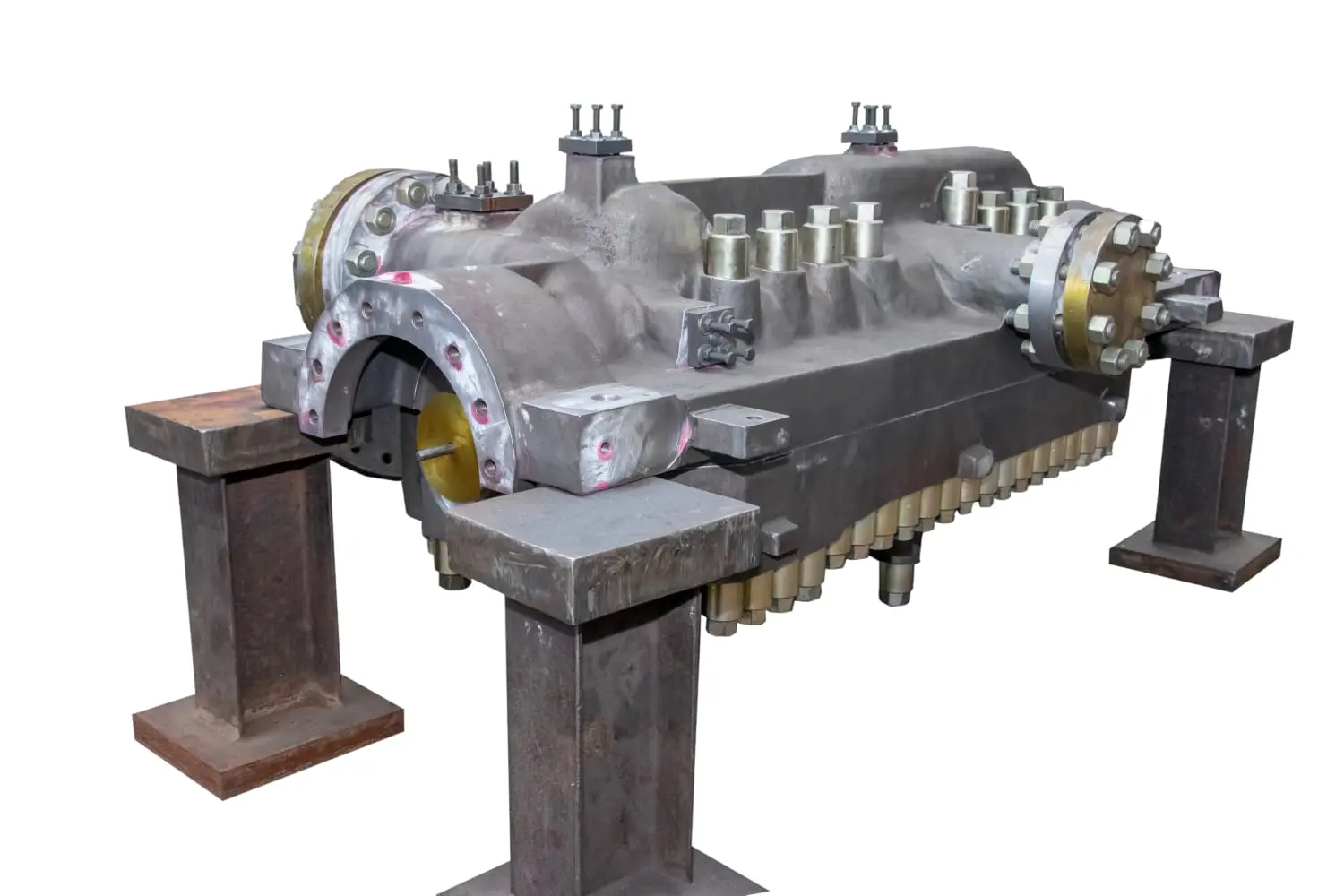

Established in 1987 by Mr. Ajay and Mr. Sanjay Jadhav, Jsons Foundry Pvt Ltd stands as the inaugural foundry unit, operating independently of any larger organization. With a current manufacturing capacity exceeding 550 tons per month and 80 tons per month Investment casting, the foundry boasts four state-of-the-art facilities equipped with cutting-edge machining capabilities.

Specializing in sand, investment, centrifugal casting units, and machine shop operations, Jsons Foundry Pvt Ltd is known for producing high-quality castings in various grades, including steel, alloy steel, corrosion-resistant stainless steel, super duplex, and high nickel alloys. The foundry delivers fully machined, ready-to-use components with casting capabilities ranging from 500 grams to 1400 kilograms per single piece. Adhering to international standards like ASTM, DIN, BS, EN, JIS, and customer specifications, Jsons Foundry Pvt Ltd is committed to providing prompt and professional responses, aiming to exceed all inquiries and requirements.

Materials

Our teams technical experience allows us to handle wide range of steel alloy

Carbon Steel

ASTM

WCB, WCA, WCC, WC1

DIN

1.0466, 1.0455, 1.0619

Low Temp, Application Steel

ASTM

LCB, LCC, LC3, LC1

DIN

1.0566,

Low Alloy Steel

ASTM

WC6, WC9, C5, C12, C12A G17Cr-Mo. 5-5 & 5-10

DIN

1.7335, 1.7380, 1.7362

Martensitic Steel

ASTM

CA15, CA6NM, CA6NM Class B

DIN

1.4317

Austenitic Stainless Steel

ASTM

CF8, CF8M, CG8M, CF3, CF3M, CF8C, CN7M, CF10, CN3MN, CG3M, CK3MCuN, CU5MCuC

DIN

1.4301, 1.4401, 1.4306, 1.4404, 4.4550

Duplex Steel, Super Duplex

ASTM

1B, 2A, 3A, 4A, 5A,6A

DIN

1.4501, 1.4462

Nickel Base Alloy

ASTM

Monel (M35-1, M35-2, M30C), Hastelloy C and B, Cu5MCuC, CN3MN, CT40, CZ100, CW12MW, CW6M, CX2M, CN7M, CK3MCuN

Nickel Aluminium Bronze

ASTM

C95500, C95800, C95820

High chrome

A532 Type III

Facilities

Induction Furnace

Melting facilities with 1MT x 2 Nos, 2MT x 2Nos, 500KG x 1 Nos , 300 KG x 2 Nos and 150 KG x 1 Nos medium frequency induction furnace

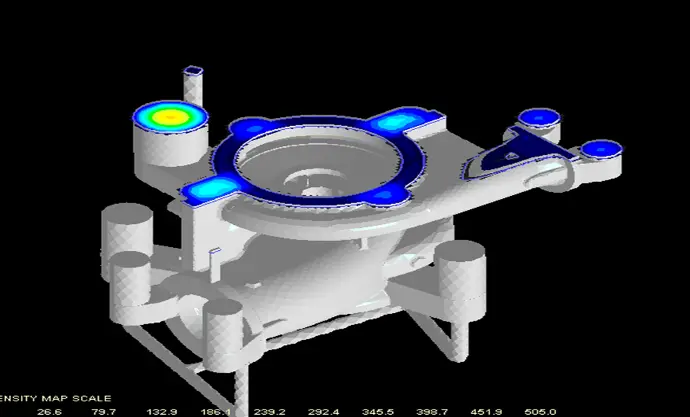

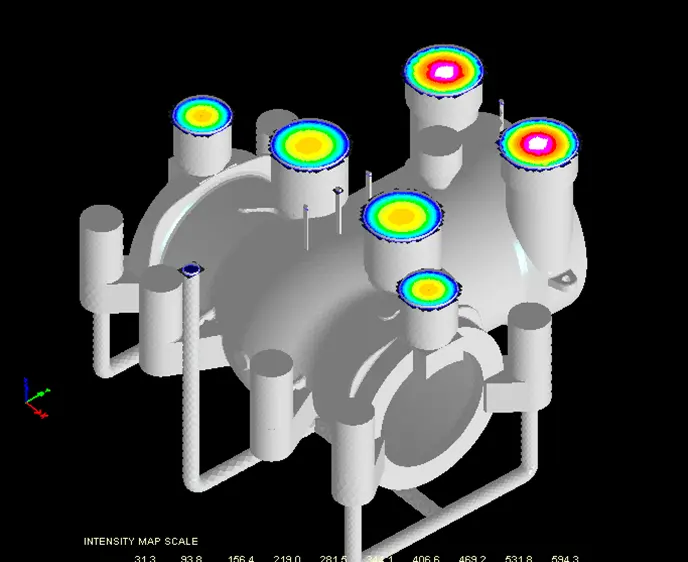

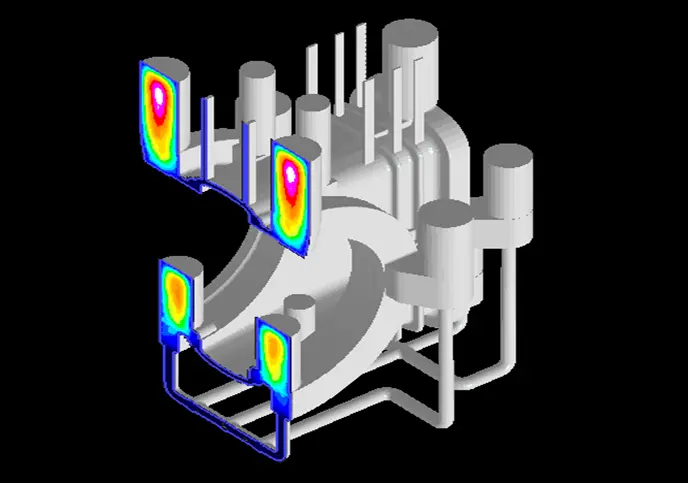

Simulation Software

Simulation software to check the soundness of casting before pouring.

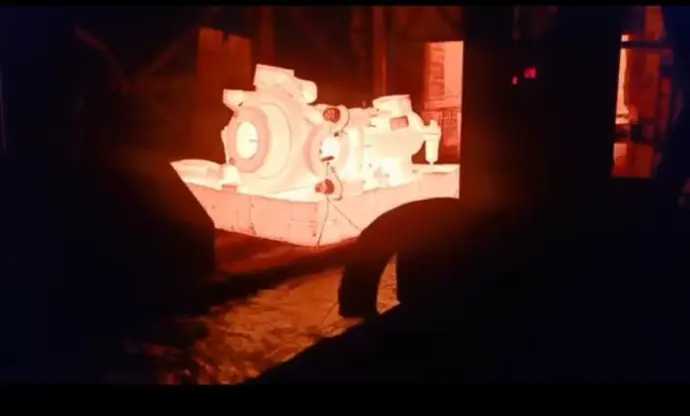

Heat Treatment

Heat Treatment furnace - 03 Nos of Bell Type Gas Fired heat treatment furnace with quenching facility

NABL Lab

Set Standards for testing and calibration laboratories to ensure they meet specific criteria for quality standards accuracy and reliability

Facilities for Testing

Scanning by Faro arm

Offering precise and efficient scanning solutions that enhance quality control and streamline production processes.

U.T.M

Model FSA model TUV 400

Impact Testing

Impact test facility done upto -196 degree celcius

Radiography Enclosure

In Total 6 Enclosures

4 Nos Iridium, 2 Nos Cobalt

Spectrometer

Spectro analysis of 30 Element- Cu,Ni,Fe Base

- ASTM G48 METHOD A/B/C/E

- ASTM A923 METHOD-A/B/C

- ASTM A262 Pr- A/B/C/E/F

- ASTM G28 METHOD-A

- ASTM A923 METHOD A

- ASTM E407

- ASTM A262 Pr-A

- MICROSTRUCTURE ANYLISIS AS PER

- ASM Handbook Vol-IX

- ASTM E112

- ASTM E562

- ASTM E1351

Non-Destructive Testing

- MP Test - Yoke Type, Probe Type

- DP Test - Solvent Base, water Washable

- UT Test - Radiography Enclosure - Linac -01, IR-01, Co-03 qty

Quality Control

- Softcast Simulation

- Faro Edge Arm for 3D Scanning and GD & T

Laboratory

- Spectrometer with 32 channels

- Ferritoscope

- Digital Hardness Tester

- Impact Testing Machine

- Universal Testing Machine

- In-Situ

Simulation Software

By simulating various casting techniques, such as sand casting or investment casting, this software allows for the optimization of Mold design, gating systems, and process parameters. Through virtual experimentation, potential defects like porosity, shrinkage, and distortion can be identified and mitigated prior to physical production, saving both time and resources. Furthermore, simulation software enables engineers to explore alternative designs and materials, facilitating innovation and continuous improvement in casting processes. Overall, the integration of simulation software in casting manufacturing empowers manufacturers to achieve higher quality, reduce costs, and accelerate time-to-market for their products.

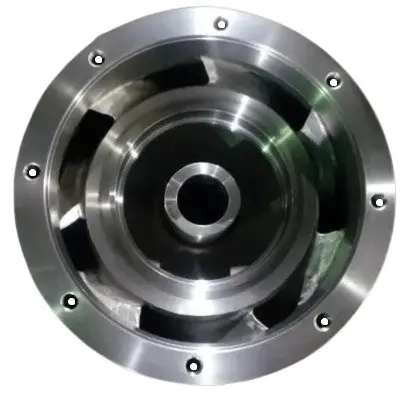

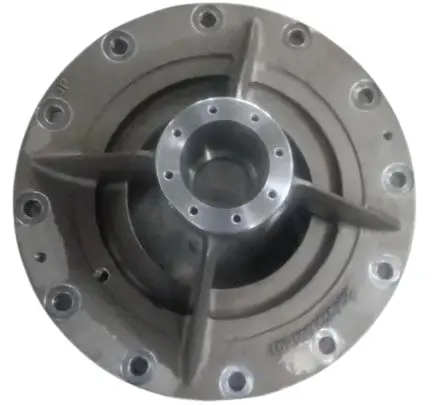

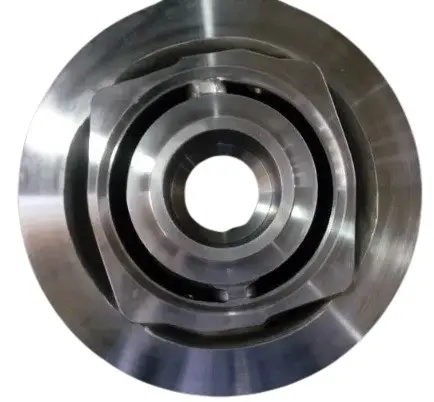

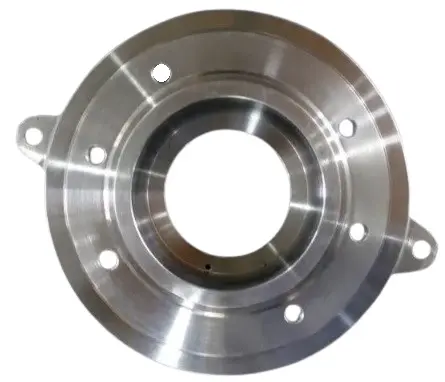

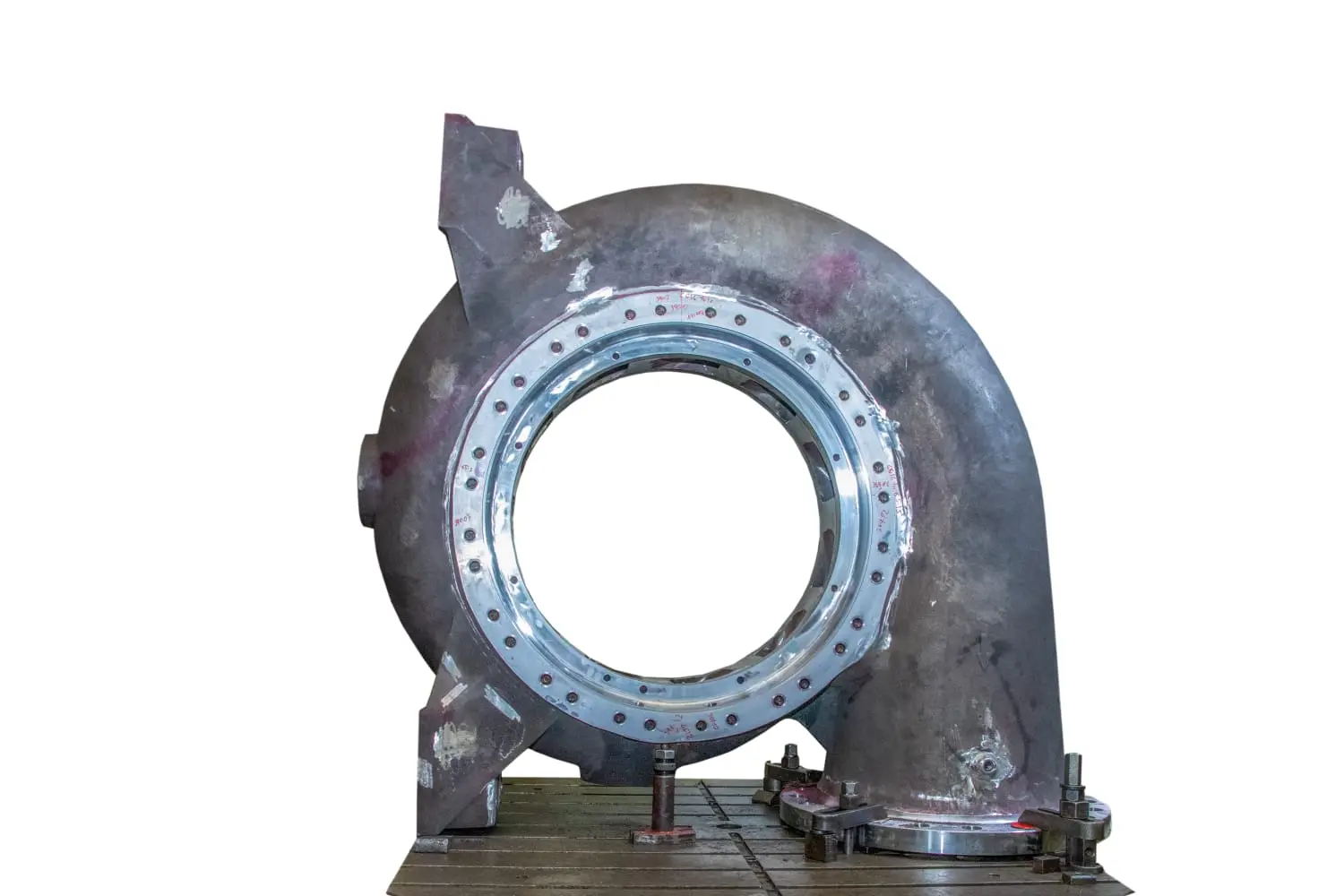

Gate Valve Body

Gate Valve Body