Western Preccast - ユニット II

月産能力 300MT

300kg~3000kg/個

Western Precicast Pvt Ltd Unit 2 specialized in manufacturing of world class casting.The company is being operated by young techno-commercials with a view to cater domestic and international requirements of Carbon steel, Alloy steel, Stainless steel, Duplex Steel, Super Duplex and Nickel alloys in raw, proof machined and finish machined conditions meeting international standards in terms of quality with on timely deliveries.

In the process of expansion and to keep up with customer requirements, we have of 2 & 5 MT capacity, Induction furnaces of 20 & 25 MT, EOT cranes.The company current production capacity is 3000 MT per annum in which we are capable to manufacture castings ranging from 200 Kg. to 3500 Kg. single piece casting.We have automatic Rapid Quenching Heat Treatment Furnace are installed and commissioned.The entire plant is spread over 14,600 sq.m. area. Utilizing advanced simulation software for methoding.We ensure precision & efficiency in our production process. At Western Precicast Precicast Pvt Ltd Unit 2 casting quality is our commitment.We are well equipped with MPI, DPI testing facilities along huge Radiography enclosures with capacity Cobalt 02 Nos.(100 Curies) enclosures .Iridium 02 Nos.(60 Curies) enclosures .We have state of art spectrometer with 29 channel for precise chemical composition analysis.

We have best in house testing facilities like UTM,Impact Testing Machines,Digital Hardness tester,Brinell Hardness Machine.WPPL Unit 2 take pride in our advanced facilities & unwevering dedication into deliverying high quality precision engineered products that meets & exceeds industry standard.

We have all the ultra-modern quality assurance facilities that ensure the customers total castings solutions. Currently we are catering to requirements of pumps, valves, turbines and process equipment under reputed third party inspecting agencies such as TUV, Lloyd, DNV, IRS, BVQI etc. Western Precicast Pvt Ltd Unit 2 having International certification of ISO 9001 -2015,Directives 2014/68/EU(PED),A0-2000 Merkblatt W0, API 20A.for Carbon steel & Stainless Steel grade. Our motto is to have a timely supply of products with consistent quality and satisfying customer requirements.

Our Certifications

Driving Growth: Western Precicast's Annual Tonnage Production

At Western Precicast, our commitment to excellence is evident in the impressive yearly tonnage produced through our manufacturing processes. Each year, our state-of-the-art facilities tirelessly churn out substantial tonnages of high-quality products, reflecting our dedication to meeting the demands of our clients and industry standards. Our unwavering focus on efficiency, innovation, and precision allows us to consistently achieve remarkable production volumes while maintaining exceptional quality standards. The accompanying bar chart visually depicts the upward trajectory of our yearly tonnage production, showcasing our continuous growth and unwavering commitment to excellence in manufacturing.

Facilities

Induction Furnace

Melting facilities with 4MT, 5MT and 6.5 MT medium frequency induction furnace

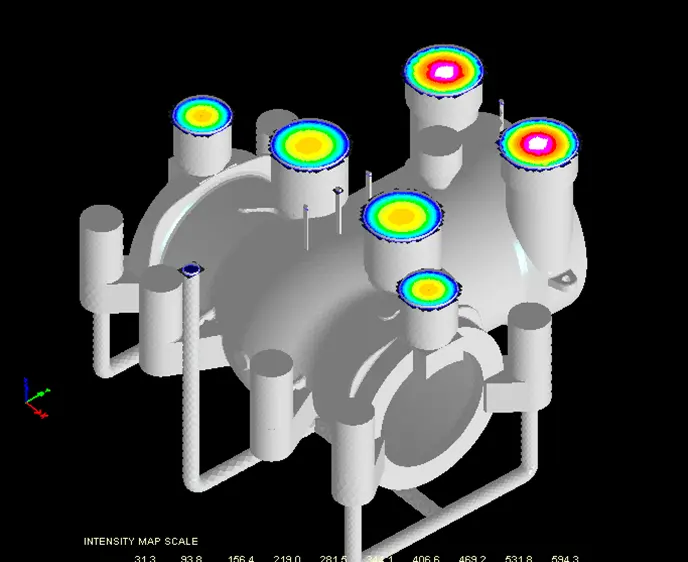

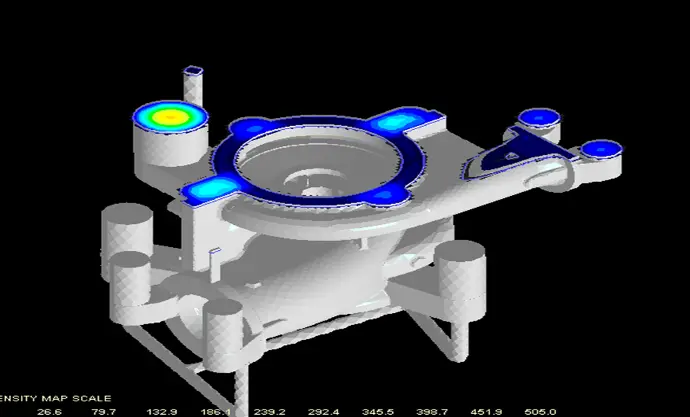

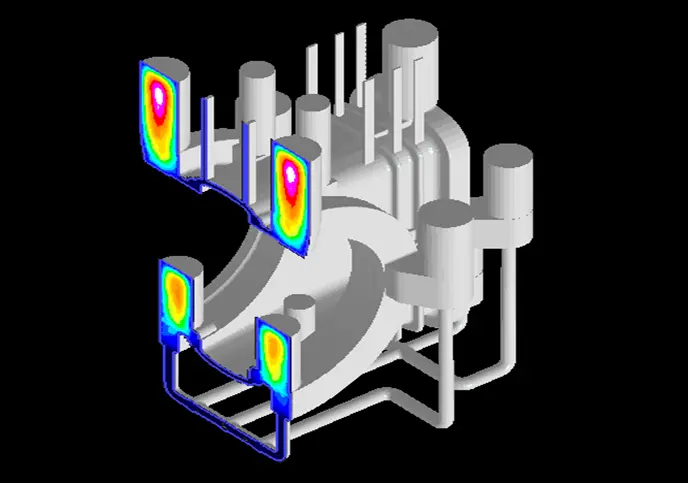

Simulation Software

Simulation software to check the soundness of casting before pouring.

Heat Treatment

Heat Treatment furnace - 03 Nos of Bell Type Gas Fired heat treatment furnace with quenching facility

Omega Sand Mixer

Qty- 2 in molding shop and 1 in core shop. Molding 20 ton per hour Core- 10 ton per hour.

試験・検査設備

Faro アームによるスキャン

品質管理を強化し、生産プロセスを合理化する、正確で効率的なスキャン ソリューションを提供します。

U.T.M

品質管理を強化し、生産プロセスを合理化する、正確で効率的なスキャン ソリューションを提供します。

衝撃試験

材料の強度と耐久性により、製品が品質基準と安全規制を満たしていることを保証します。

X線撮影用エンクロージャ

Up to 300 mm Thickness

09 X線撮影用エンクロージャ - Co-60 5台、Ir-192 3台、LINAC - 6Mev

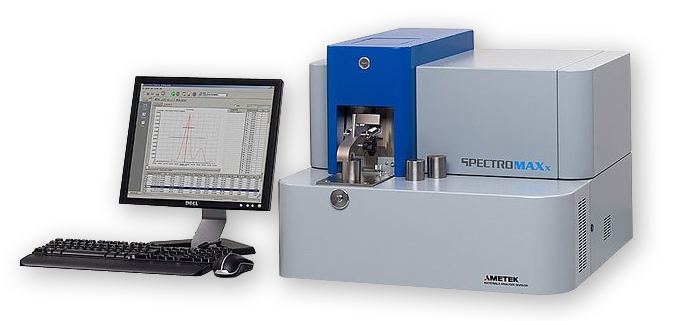

Spectro - 化学分析用

2 Nos Spectro およびすべての社内化学および機械試験施設。

PMI - 作業中の化学物質をチェックするには

Corrosion Test

- ASTM G48 METHOD A/B/C/E

- ASTM A923 METHOD-A/B/C

- ASTM A262 Pr- A/B/C/E/F

- ASTM G28 METHOD-A

Metallography

- ASTM A923 METHOD A

- ASTM E407

- ASTM A262 Pr-A

- MICROSTRUCTURE ANYLISIS AS PER

- ASM Handbook Vol-IX

- ASTM E112

- ASTM E562

- ASTM E1351

Simulation Software

By simulating various casting techniques, such as sand casting or investment casting, this software allows for the optimization of mold design, gating systems, and process parameters. Through virtual experimentation, potential defects like porosity, shrinkage, and distortion can be identified and mitigated prior to physical production, saving both time and resources. Furthermore, simulation software enables engineers to explore alternative designs and materials, facilitating innovation and continuous improvement in casting processes. Overall, the integration of simulation software in casting manufacturing empowers manufacturers to achieve higher quality, reduce costs, and accelerate time-to-market for their products.

There is no magic, it's time to get the tools you deserve.

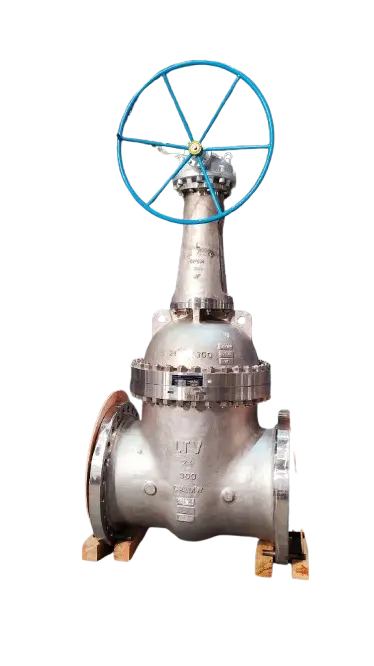

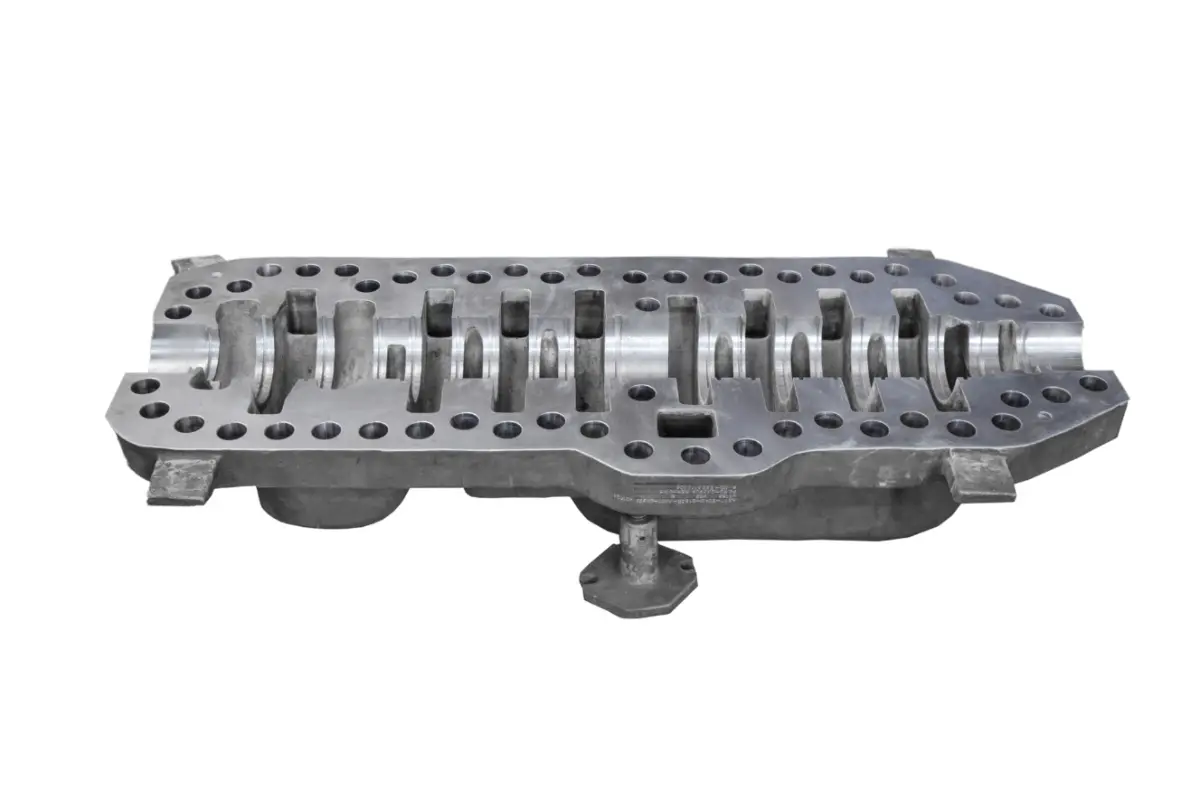

Gate Valve Body

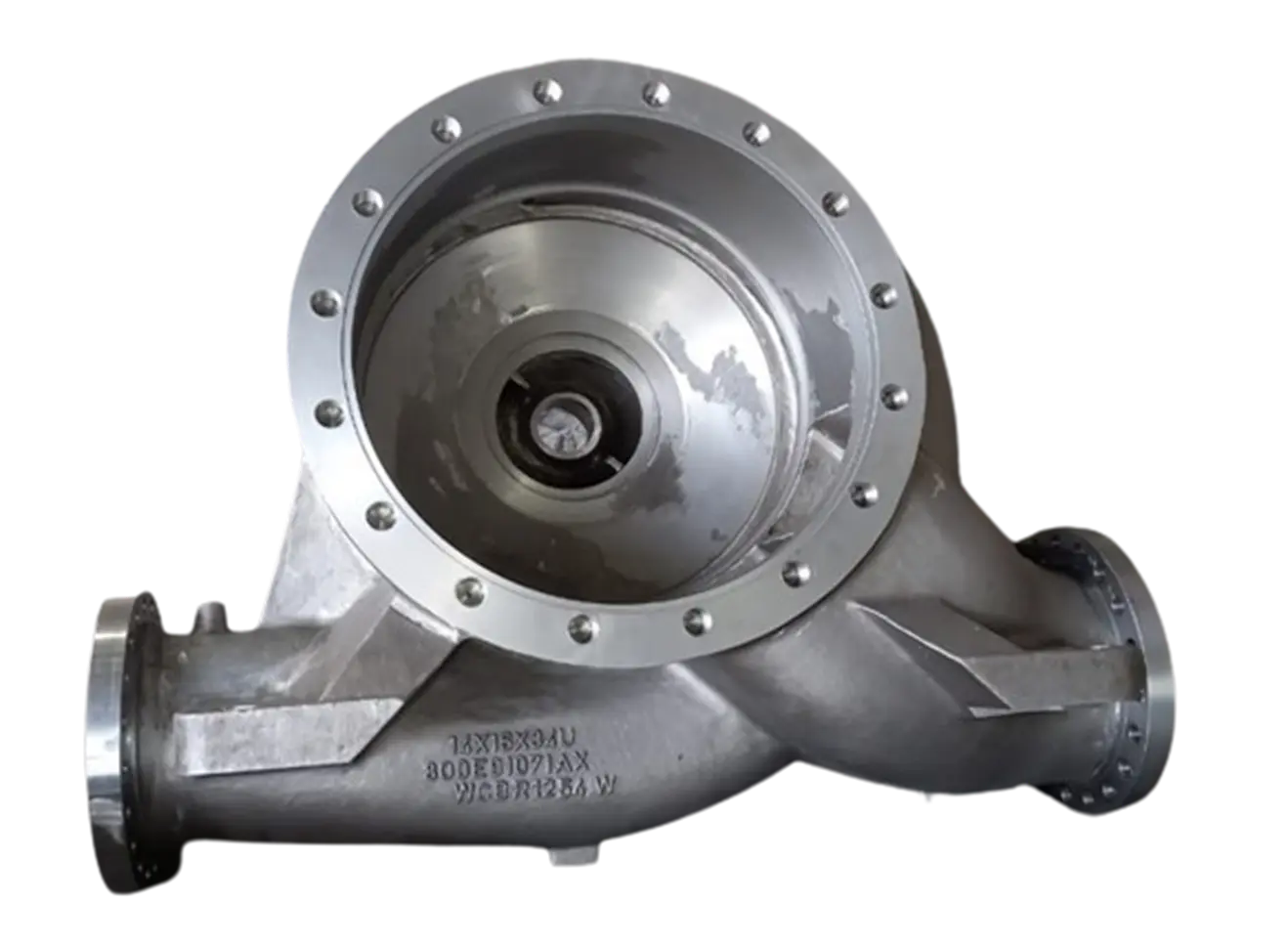

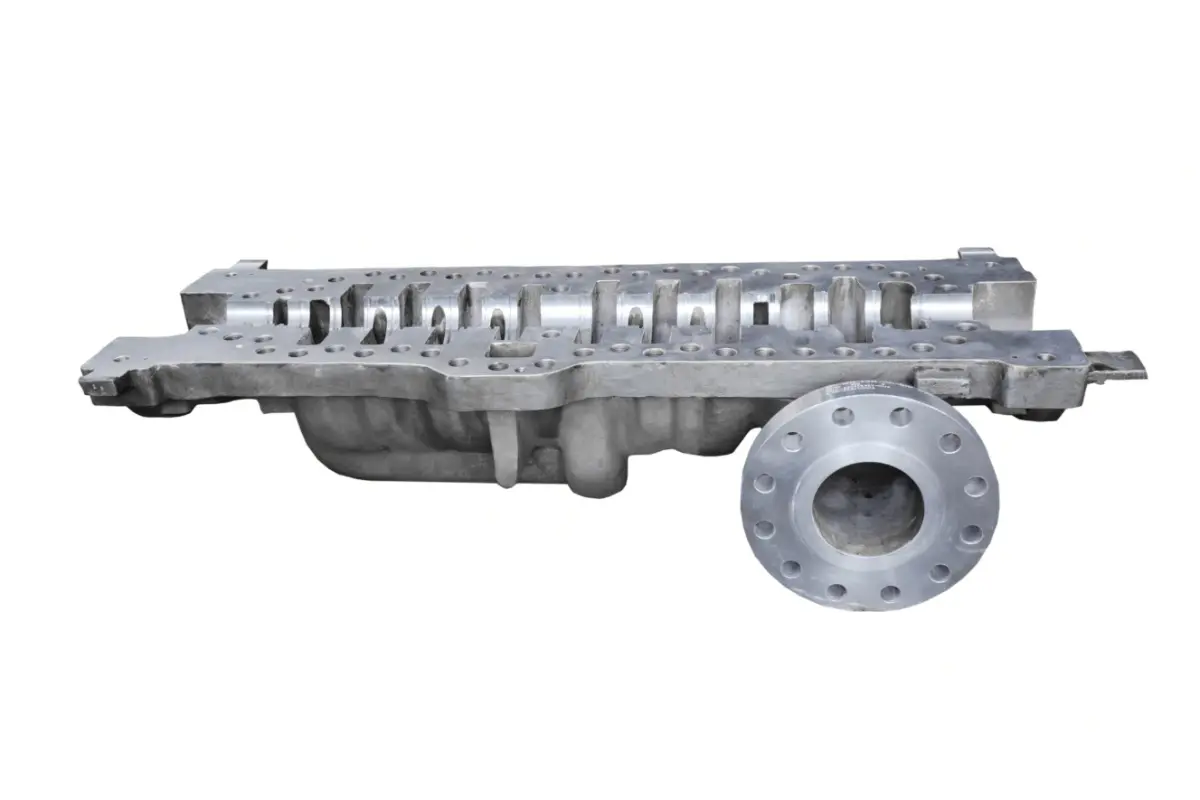

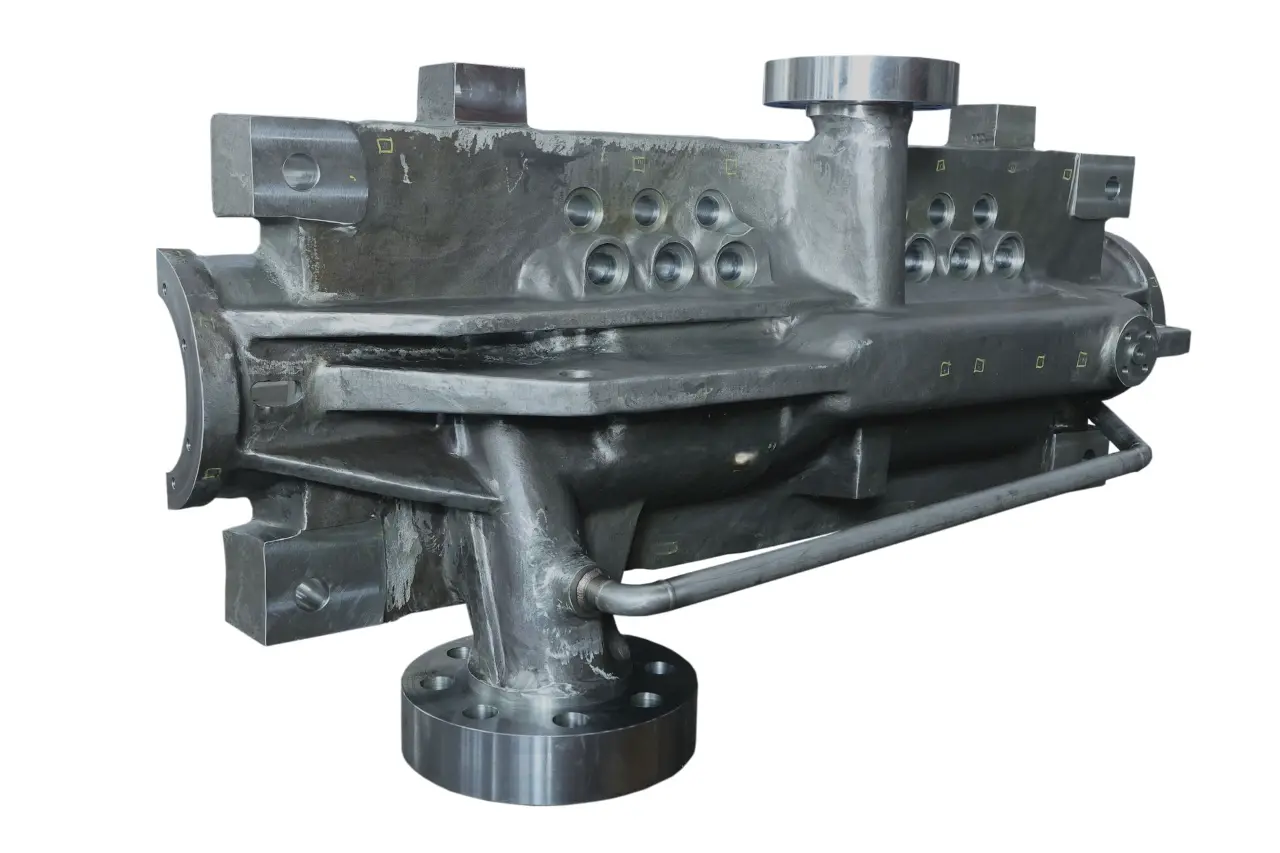

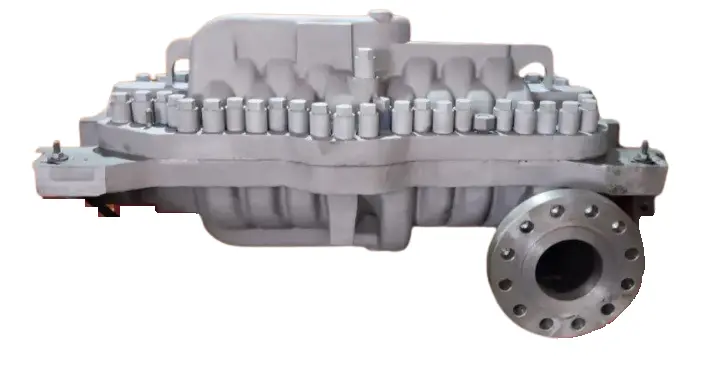

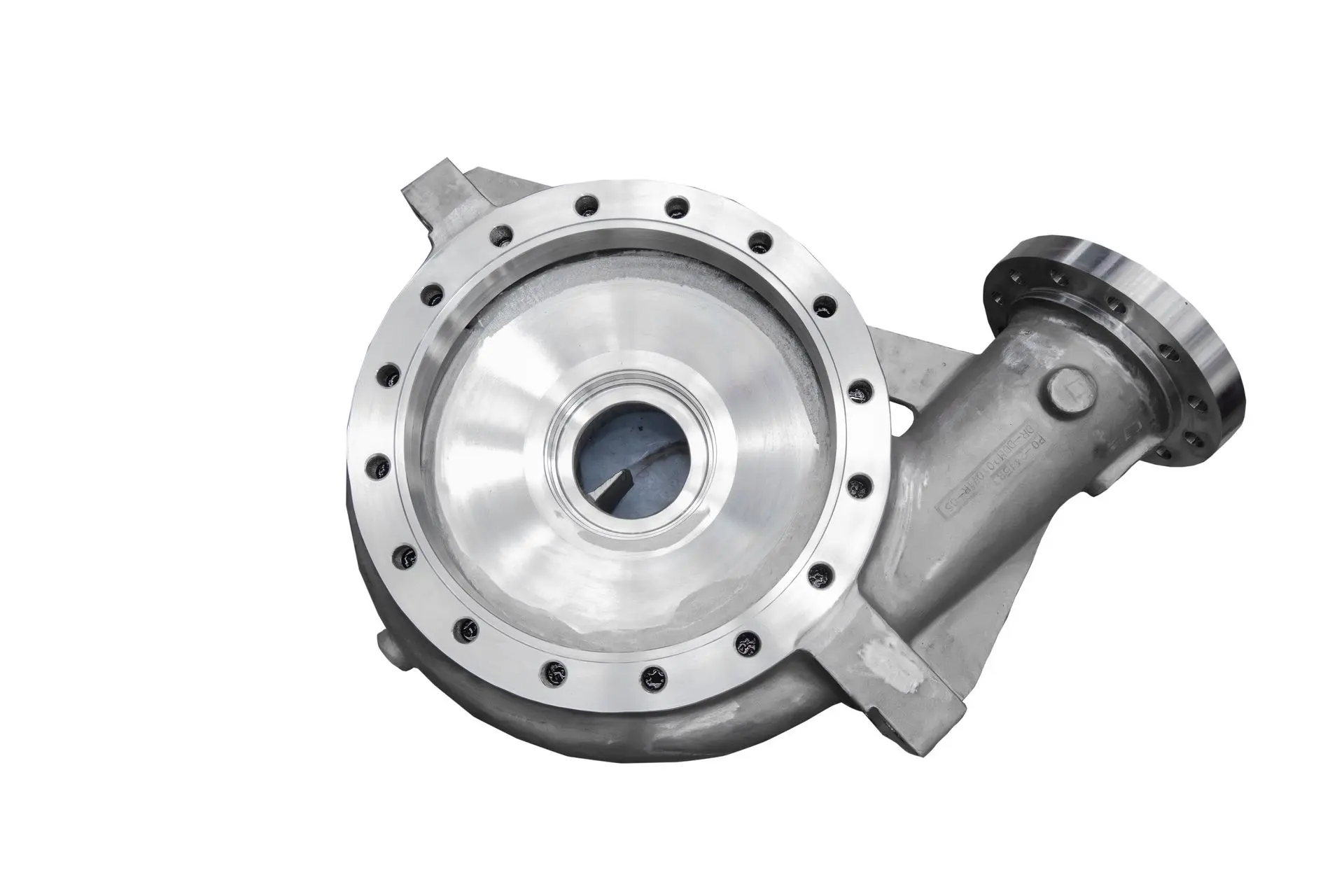

Pump Casting

Gate Valve Body

Facilities Available for Quality Control

Non-Destructive Testing

- MP Test - Yoke Type, Probe Type

- DP Test - Solvent Base, water Washable

- UT Test - Radiography Enclosure - Linac -01, IR-01, Co-03 qty

Quality Control

- Softcast Simulation

- Faro Edge Arm for 3D Scanning and GD & T

Laboratory

- Spectrometer with 32 channels

- Ferritoscope

- Digital Hardness Tester

- Impact Testing Machine

- Universal Testing Machine

- In-Situ